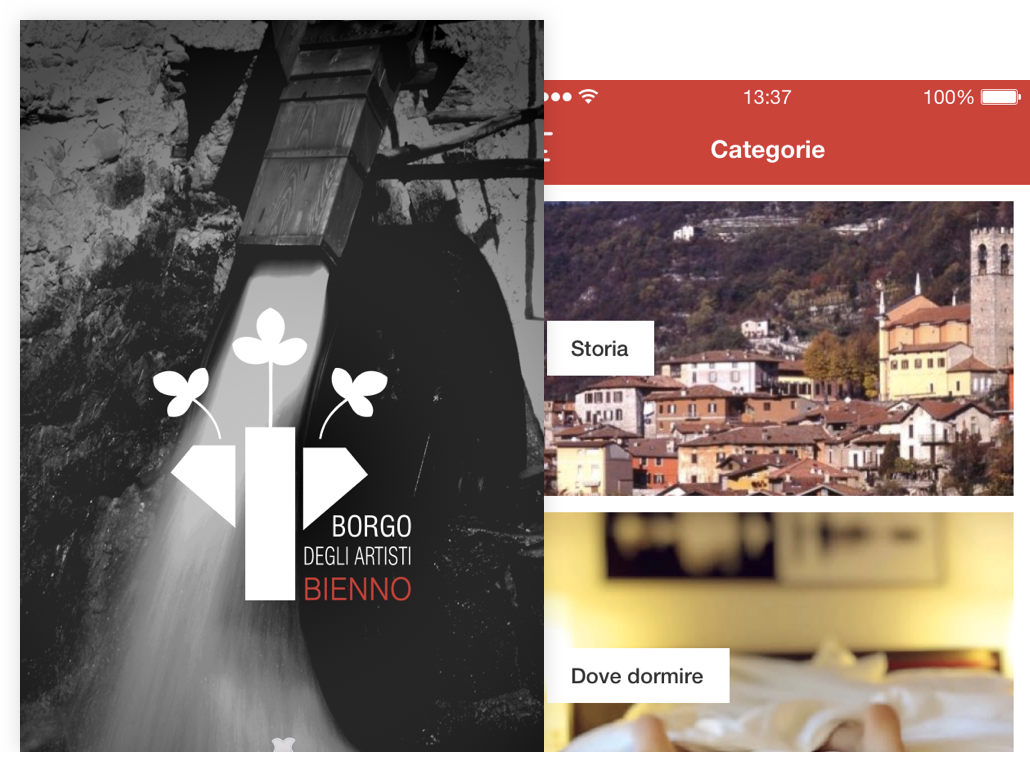

Bienno, Borgo dei Magli e degli Artisti

Ti diamo il benvenuto nel sito turistico ufficiale del Comune di Bienno... scopri il nostro Borgo medievale partendo da qui!

ScopriScopri Bienno!

SCARICA QUI la mappa turistica del Borgo con tutte le informazioni necessarie per la tua visita!

ScopriImmergiti nella sua storia...

Vieni alla scoperta delle peculiarità di uno dei Borghi più belli d'Italia!

ScopriPunti d’interesse

Dalla storia del Borgo ai Luoghi da visitare passando per il progetto “Bienno Borgo Artisti 2.0”, scopri dove dormire, dove gustare i piatti tipici del territorio e tutti i servizi offerti a chi decide di trascorrere del tempo a Bienno!

ScopriOfferte turistiche

Vivi Bienno! Scopri le offerte turistiche proposte dall’Associazione Bienno turismo nell’arco dell’anno... ti aspettiamo!

Eventi

Un calendario di eventi così ricco da non sembrar vero! Ogni mese un appuntamento diverso pronto ad accontentare i gusti di tutti... grandi e piccini.